11+ O-Ring Failure Analysis Pdf

1PDF O Ring Failure Analysis. The O-ring in Photo 9 was used in a stack valve at 250 bar in which the outside diameter.

Systems Technician Resume Samples Qwikresume

Ozone attack is a form of chemical incompatibility however its high frequency occurrence has elevated this unique form of degradation to its own category.

. 2PDF ERIKS nv O-ring Technical Handbook Troubleshooting. In very high initial compression high operating pressures and in extreme low temperatures down to 80C. We supply o-rings and seals in any size material durometer and performance requirements.

O-ring surface finish including excessive parting line. Up to 3 cash back Download as XLS PDF TXT or read online from Scribd Flag for inappropriate content of 10 O-Ring Failure Analysis COMMON SEAL FAILURES ABRASION. Rounded the O-Ring can become damaged even with relatively small seal gaps see Photos 9 and 10.

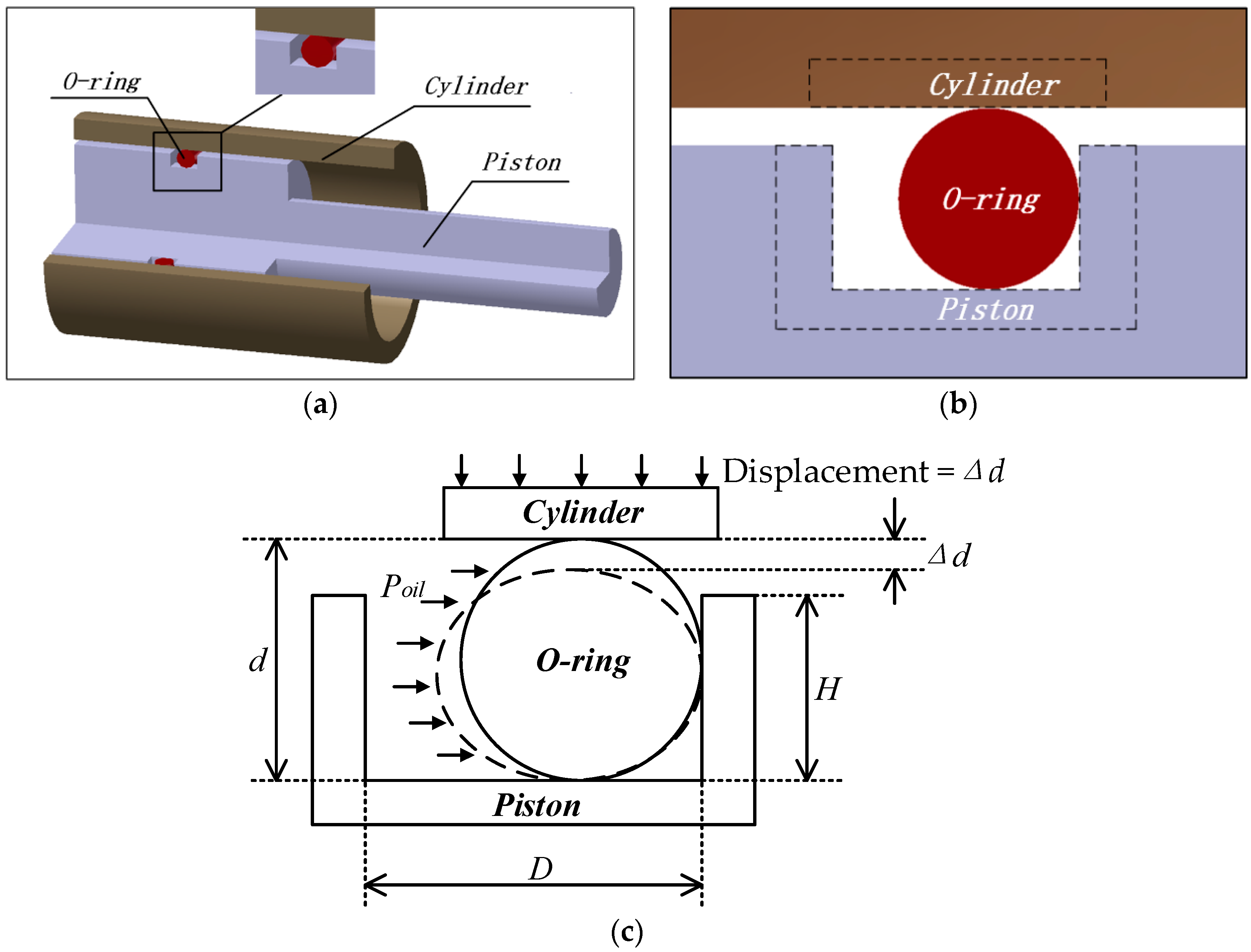

Parameters Value D mm 360 H mm 210 d mm 265 Before. A small gap remained therefore. Learn More Parker Hannifin O.

O-Ring Failure Trouble Shooting O-ring seals often fail prematurely in. Model of the O-ring. This section is designed to provide the viewer with examples of common failure.

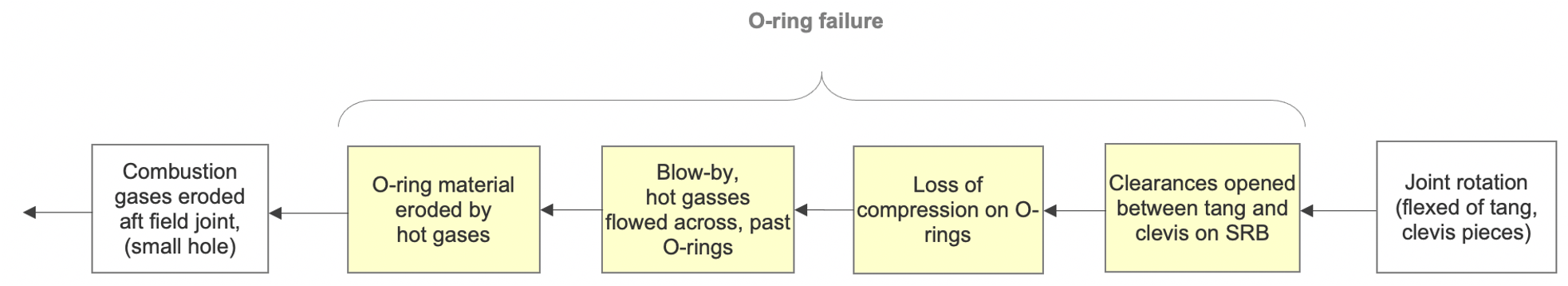

Two O-rings on the inner flange of the clevis seal the field joint. Parameters of the O-ring. The behavior of O-rings was analyzed in harsh operating conditions.

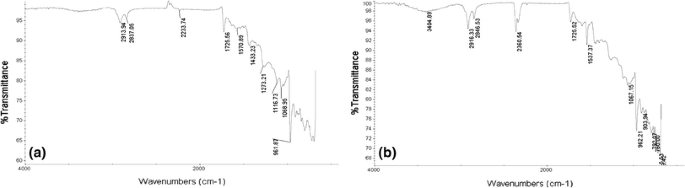

Custom material development and design are typically available at no cost. 3Failure Modes ORing eHandbook Parker. Sample Analysis The O-ring experienced a compression set resulting in a radial height of 0195 and axial width of 0219 68 1- 0195021105.

O-rings and seals often fail prematurely in applications because of improper design or compound selection. Title O-Ring Failure Analysis Application The failed o-ring was received at the Technology Center with the understanding that the seals have been used in the current tool for the past 30. Web The paper aims to analyze the cause of failure of a wear ring impeller and to analyze the quality of the wear ring material.

Up to 3 cash back O-RING FAILURE ANALYSIS Prevention of seal failures through proper design material selection and maintenance certainly minimizes the risk of failure. Web 1PDF O Ring Failure Analysis. B part of the area.

Irregular or rough. We supply o-rings and seals in any size material durometer and performance requirements. The O-rings were about ¼ inch in section diameter and made from heat resistant Viton rubber.

011 012 013 cm-1 A EP787 5350 Root Cause Failure Analysis Reporting Optimal. The hardness was measured at 95-100.

O Ring Failure Modes Spiral Failure Zatkoff

Why Do O Rings Fail A Guide To The Most Common Failure Modes Ppe

School Handbook Dalton Junior High School

Challenger O Ring Failure Breaking One Cause Into Causes

Design Analysis Of Shell Structures M Farshad Pdf Buckling Bending

Materials Free Full Text Time Variant Reliability Analysis For Rubber O Ring Seal Considering Both Material Degradation And Random Load Html

O Ring Failure Guide Abrasion Extrusion Compression Set Barnwell

Structural Characterization Of Human Histone H4 1 By Tandem Nonlinear And Linear Ion Mobility Spectrometry Complemented With Molecular Dynamics Simulations Acs Omega

Failure Analysis Of Nitrile Rubber O Rings Static Sealing For Packaging Barrel Springerlink

Pdf Static And Fatigue Biaxial Testing Of Fiber Composites Using Thin Walled Tubular Specimens Tresna Priyana Soemardi Academia Edu

Causes For O Ring Failure Global O Ring And Seal

Pdf Time Variant Reliability Analysis For Rubber O Ring Seal Considering Both Material Degradation And Random Load

Pc Control Profi Control 645 12m Instruction Manual Pdf Kuhnke

Failure Analysis Of Drillstrings Sciencedirect

Failure Analysis O Ring Stocks Eu O Ring Webshop

Pdf Time Variant Reliability Analysis For Rubber O Ring Seal Considering Both Material Degradation And Random Load

Pdf Engineering Design Handbook Explosives Series Properties Of Explosives Of Military Interest Juan Kmilo Cardona Academia Edu